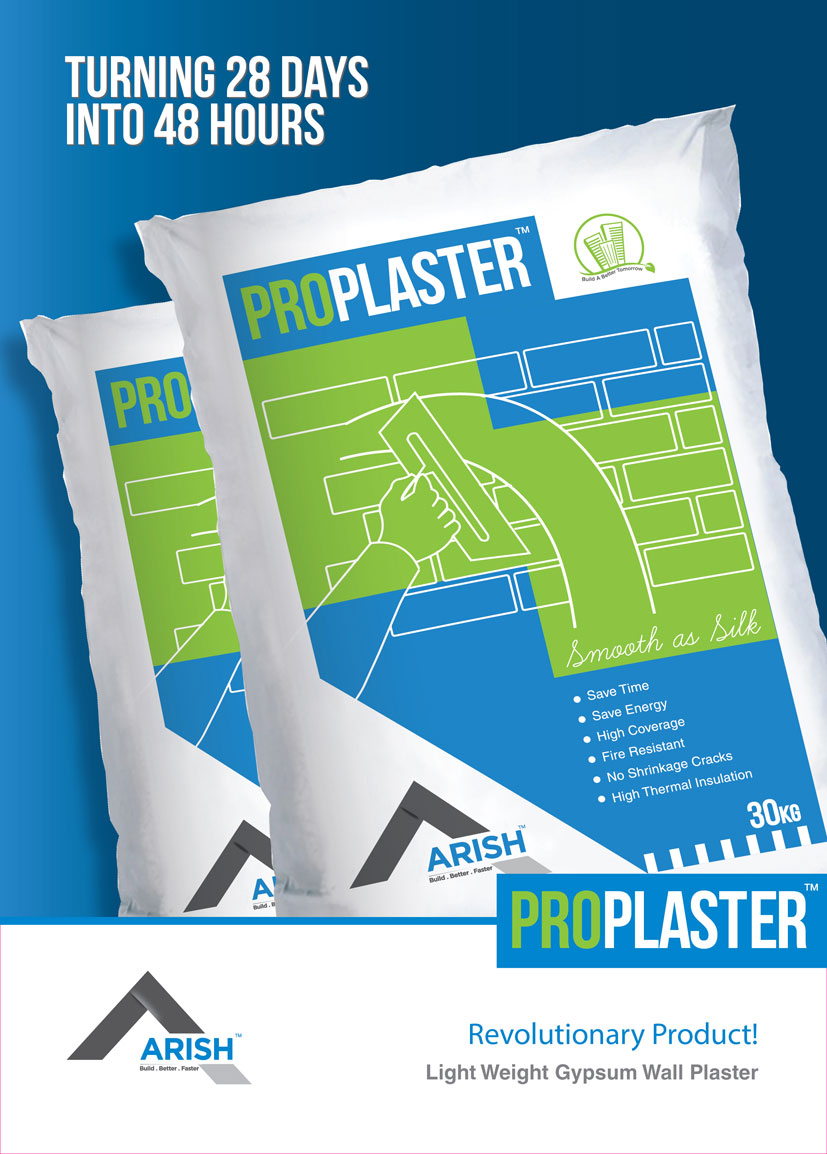

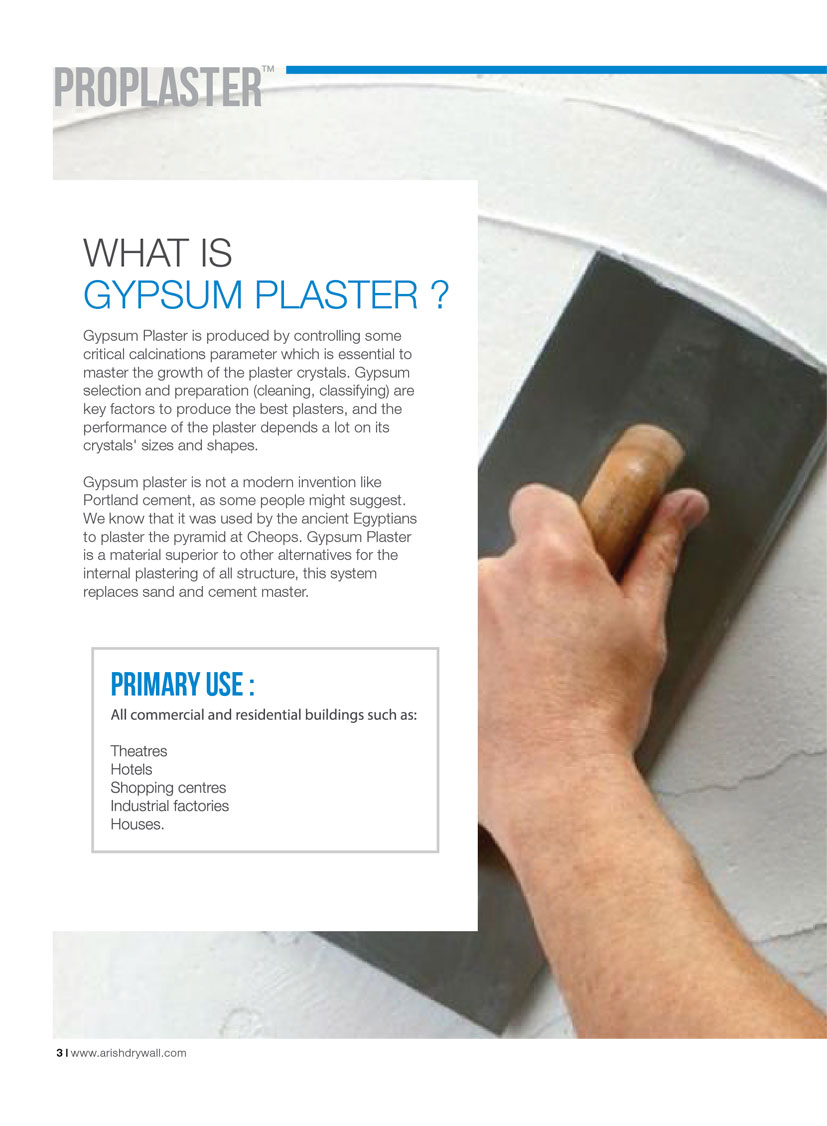

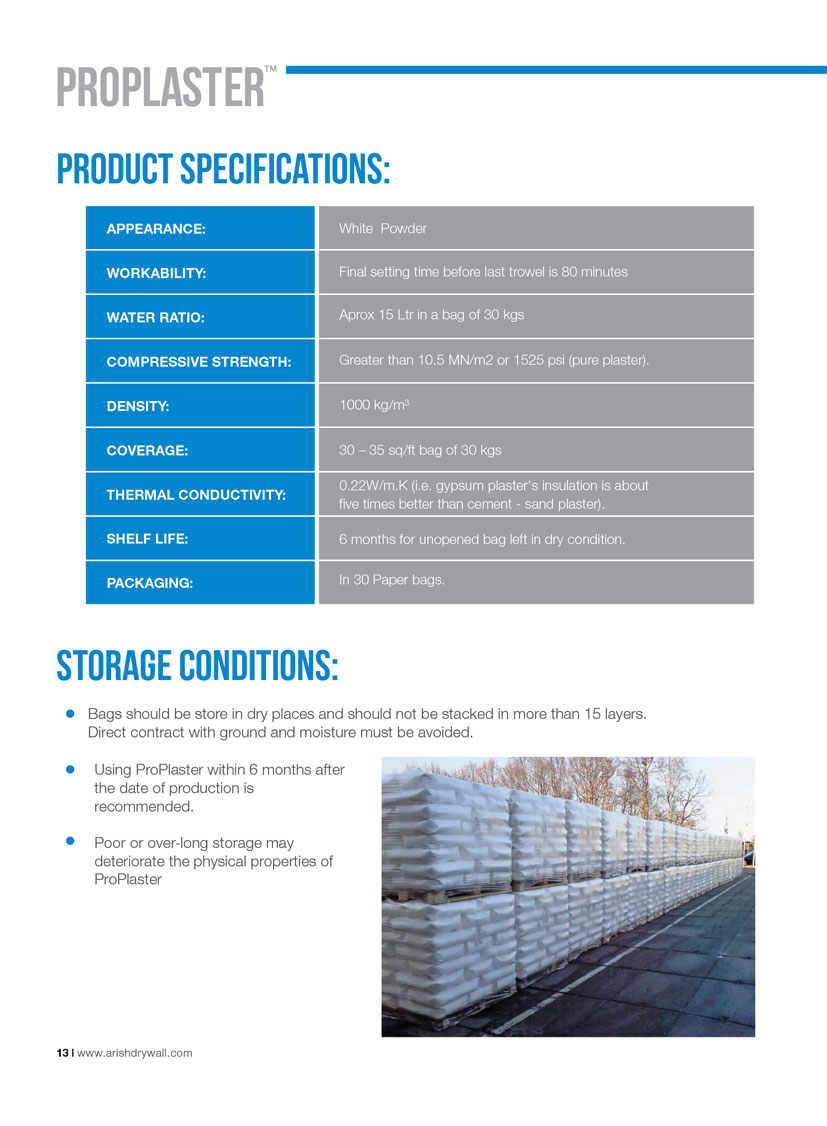

ProPlaster™ products are manufactured from the highest quality gypsum. It is designed for any type of interior wall and ceiling surfaces, providing non-combustibility, directly over porous concrete blocks

ProPlaster™ is gypsum based plaster suitable for application on most internal backgrounds including brick, block and concrete. It consists of Gypsum Hemihydrate, formulated with special additives to enhance working and setting characteristics. It is specially formulated to replace a dirty, time consuming and conventional (sand-cement) plastering methods of interior walls. ProPlaster™ is the products of an advanced technology which has attained the much-desired excellence under strict quality control system.

ProPlaster™ provides smooth, silky white surface ready to receive a decorative finish. It replaces a dirty and conventional masonry (sand-cement) plastering and relatively easy to work with. It contains light weight aggregates to improve plaster's workability, coverage, application and post usage behavior.

ProPlaster™ can be applied from 8mm to 25mm thick which can be either machine or hand applied, making ideal for any size of commercial or domestic applications. However, when machine applied it offers excellent productivity and is up to 3 times faster than traditional plastering methods.

|

Applications: All commercial and residential buildings such as: Theatres, Hotel, Shopping centers, Industrial factories, and houses. Good for low cost housing!

|

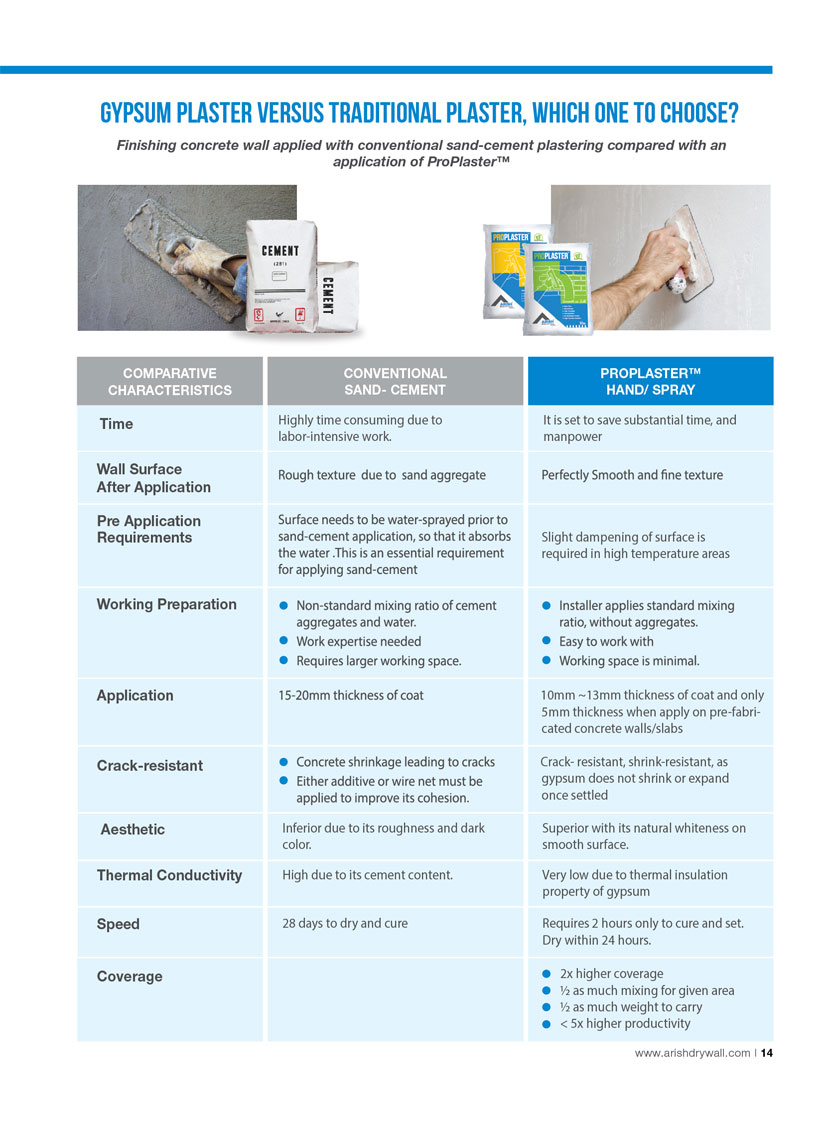

Gypsum plaster versus traditional plaster, Which one to choose?

Finishing concrete wall applied with conventional sand-cement plastering compared with an application of ProPlaster™

|

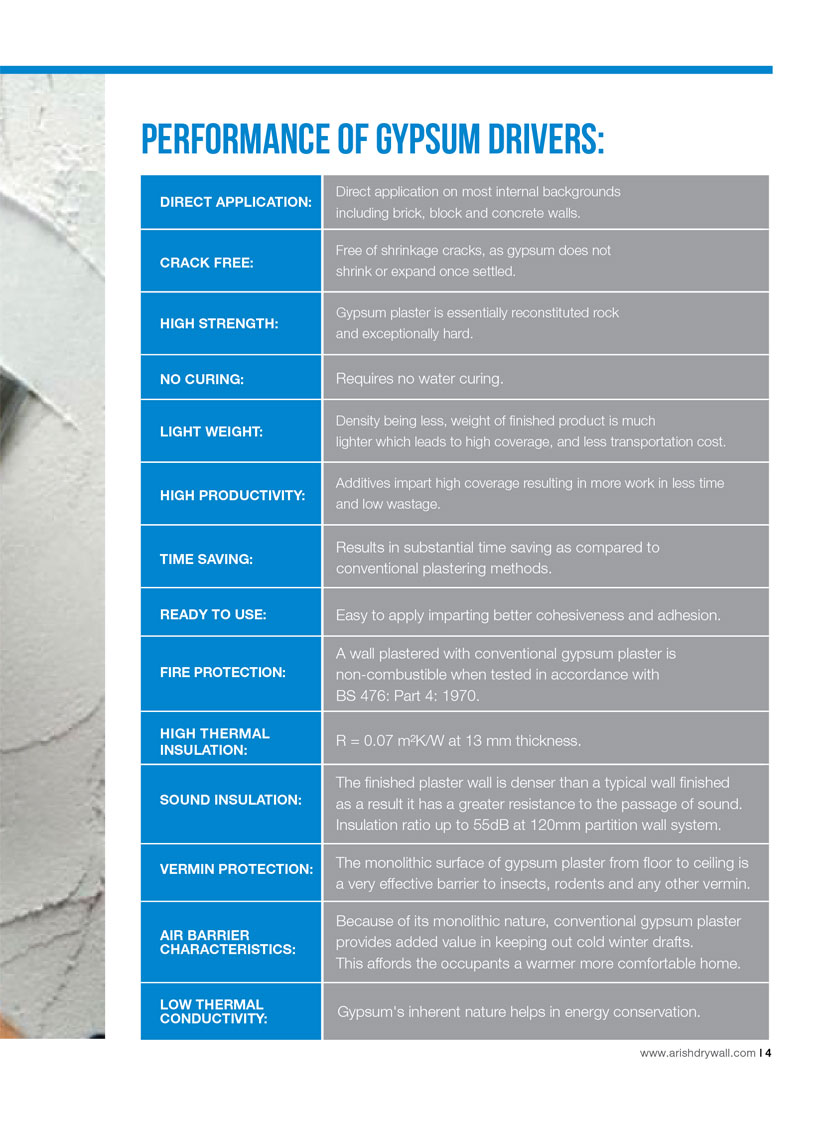

Key Facts

- One coat Putty application

- No Curing Time required.

- No primer required before painting

Features

- save substantial time

- create a smoother finish

- Decrease Energy Consumption

- Uses 58% less water than with sand and cement*

- No need of sand and cement, completely clean site.

- Reduces echoes and level of noise

- Requires less paint

- Salt resistant.

Gypsum Plaster Application Video